WHAT

IS GREEN CONCRETE?

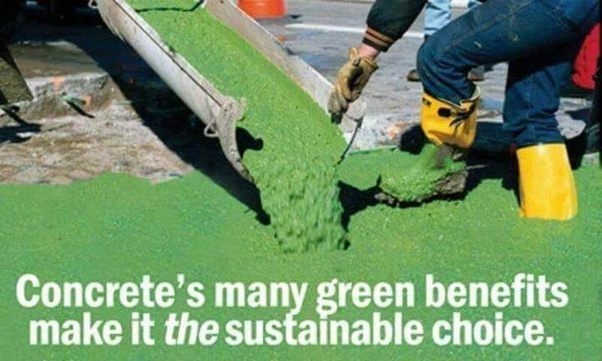

Today the word green is not just

limited to color, it represents the environment, which is surrounding us.

Concrete which is made from concrete

wastes that are eco-friendly are called as “Green concrete”.

The other name for green concrete is

resource saving Structure with reduced environmental impact for e.g. Energy

saving ,co2 emissions, waste water.

“Green concrete” is a revolutionary

topic in the history of concrete industry. This was first invented in Denmark

in the year 1998 by Dr.WG.

Concrete wastes like slag, power

plant wastes, recycled concrete, mining and quarrying wastes, waste glass,

incinerator residue, red mud, burnt clay, sawdust, combustor ash and foundry

sand.

Green Concrete is a term given to a

concrete that has had extra steps taken in the mix design and placement to

insure a sustainable Structure and a long life cycle with a low maintenance

surface. e.g. Energy saving, CO2 emissions, waste water.

The goal of the Centre for Green

Concrete is to reduce the environmental impact of concrete. To enable this, new

technology is developed. The technology considers all phases of a concrete

construction’s life cycle, i.e. structural design, specification, manufacturing

and maintenance, and it includes all aspects of performance, i.e.

1) Mechanical properties (strength,

shrinkage, creep, static behavior etc.)

2) Fire resistance (spelling, heat

transfer etc.)

3) Workmanship (Workability,

strength development, curing etc.)

4) Durability

(corrosion protection, frost, new

deterioration mechanisms etc.)

5) Thermodynamic properties (input

to the other properties)

6) Environmental aspects

(CO2-emission, energy, recycling etc.)

There are a number of alternative

environmental requirements with which green concrete structures must comply:

- CO2 emissions shall be reduced

by at least 30 %.

- At least 20 % of the concrete

shall be residual products used as aggregate.

- Use of concrete industries own

residual products.

- Use of new types of residual

products, previously land filled or disposed of in other ways.

- CO2-neutral, waste-derived

fuels shall substitute fossil fuels in the cement production by at least

10 %.

In

addition to the environmental goals there are a number of environmental

intentions. Most important are:

To avoid the use of materials which

contain substances on the Environmental Protection Agency’s list of unwanted

materials, not to reduce the recycling ability of green concrete compared with

conventional concrete and not to increase the content of hazardous substances

in the wastewater from concrete production compared with wastewater from

production of existing concrete types.

Different concrete types are tested

for workability, changes in workability after 30 min., air-content, compressive

strength development, E-modulus, heat development, homogeneity, water

separation, setting time, density and pumpability. Furthermore, frost testing,

chloride penetration and an air void Analysis are carried out for the concretes

in the aggressive environmental class.

The Water/cement ratio, water/binder

ratio and the chloride content are calculated from the mixing report of the

precise mixture proportions and from the chloride content in the different raw

materials.

ADVANTAGES

- Reduction of the concrete

industry’s CO2-emmision by 30 %.

- Increased concrete industry’s

use of waste products by 20%.

- NO environmental pollution and

sustainable development.

- Green concrete requires less

maintenance and repairs.

- Green concrete having better

workability than conventional concrete.

- Good thermal resistant and fire

resistant.

- Compressive strength behavior

of concrete with Water/cement ratio is similar to conventional concrete.

- Flexural strength of green

concrete is almost equal to that of conventional concrete.

LIMITATION

- By using stainless steel, cost

of reinforcement increases.

- Structures constructed with

green concrete have comparatively less life than structures with

conventional concrete.

- Split tension of green concrete

is less than that of conventional concrete.

0 comments:

Post a Comment